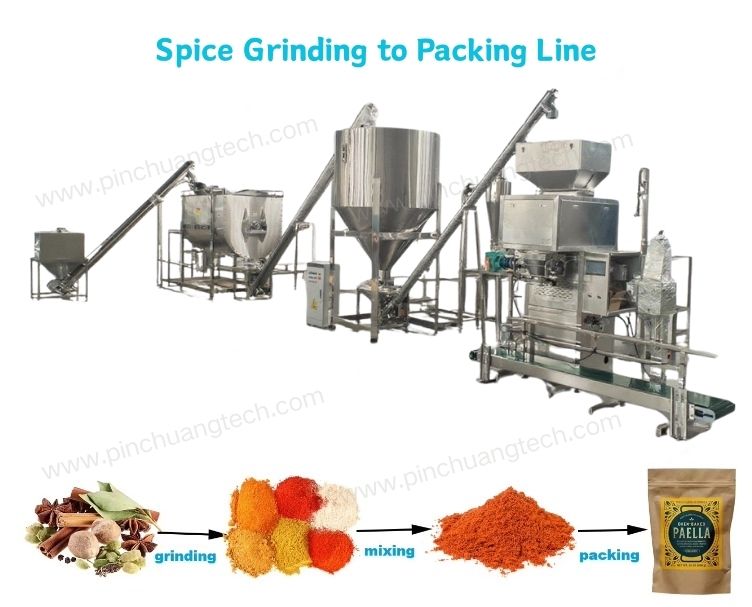

The chili powder grinding, mixing, conveying, and packing integrated production line is designed for large-scale processing of chili, Sichuan pepper, and various spices. This complete line combines grinding, dust collection, mixing, conveying, and automatic packing into one continuous process, significantly improving production efficiency, reducing labor costs, and minimizing dust pollution.

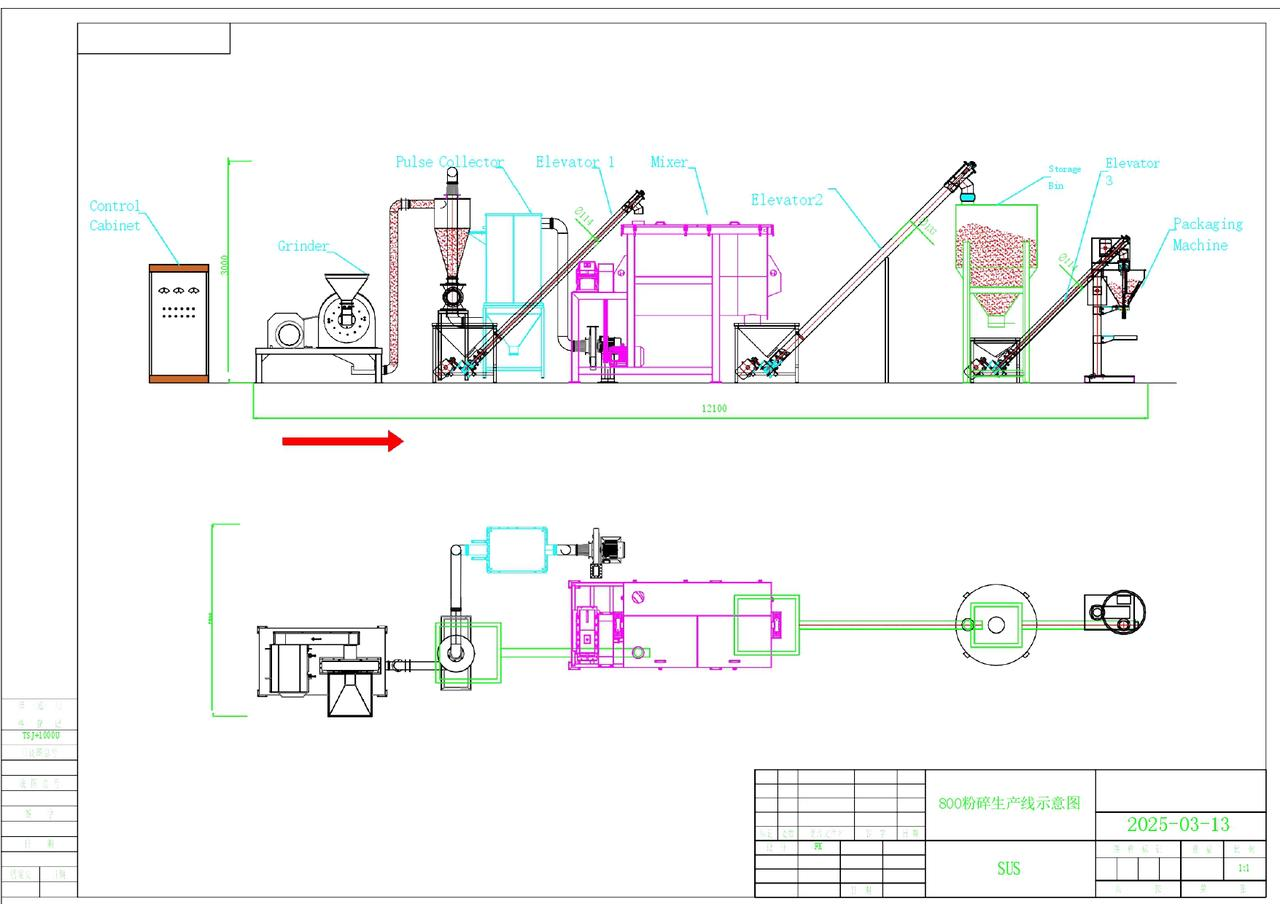

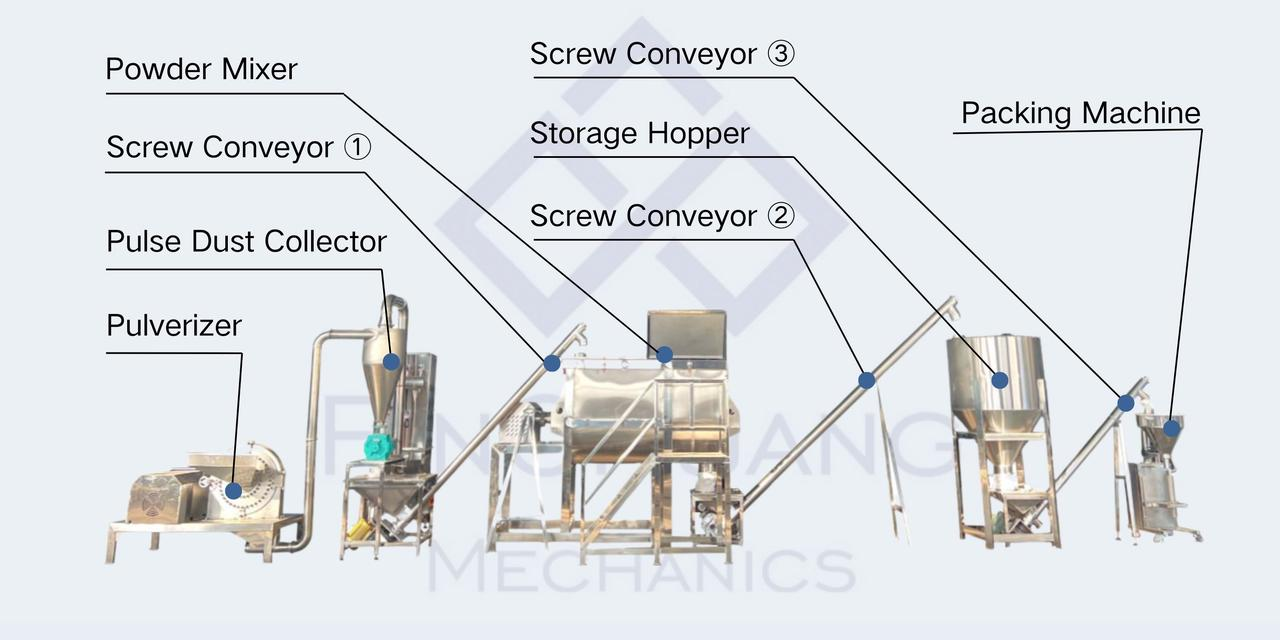

1. Composition of the Production Line

- Chili Grinder (with cyclone separator or pulse dust collector)

- High-Efficiency Mixer (horizontal ribbon or double-shaft paddle type)

- Conveying Equipment (bucket elevator or screw conveyor)

- Automatic Packing Machine (weighing, filling, and sealing system)

- Electrical Control System (centralized PLC control & monitoring)

2. Working Process

Raw Material Grinding

- Dried chili enters the grinding chamber via the feeding hopper.

- Under the high-speed impact, cutting, and shearing of the moving and fixed teeth, materials are ground into fine powder.

- Mesh size can be adjusted (10–120 mesh).

- Equipped with cyclone or pulse dust collection system to ensure a clean workshop.

Automatic Lifting & Conveying

- The ground chili powder is automatically lifted and conveyed into the mixer, reducing manual handling.

Uniform Mixing

- The mixer blends chili powder with Sichuan pepper, cumin, salt, or other seasonings.

- Mixing uniformity reaches over 95%, ensuring consistent flavor.

Automatic Packing

- Finished powder is delivered to the packing machine for weighing, filling, and sealing.

- Suitable for multiple packaging sizes (e.g., 1kg, 5kg).

3. Common Capacity Configurations

- Small Line: 300–1000 kg/h

- Medium Line: 1–2 t/h

- Large Line: 2–5 t/h

Optional features: dust collection system, frequency control, automatic weighing system.

4. Equipment Features

- High-Efficiency Grinding: claw-type grinder, fine powder up to 120 mesh.

- Full Dust Collection: cyclone or pulse system ensures dust-free and quiet operation.

- High Automation: integrated grinding–mixing–conveying–packing line saves labor.

- Food-Grade Material: made of 304 stainless steel, corrosion-resistant, easy to clean.

- Wide Applicability: suitable for spices, grains, and herbal materials.

- Safe & Controllable: PLC centralized control with touchscreen operation.

5. Application Scope

Suitable for spice factories, seasoning manufacturers, food processing enterprises, and agricultural product deep-processing industries.

Applicable materials include:

- Spices: chili, Sichuan pepper, star anise, cinnamon, bay leaf, cumin, etc.

- Grains: wheat, corn, rice, black beans, soybeans, glutinous rice, etc.

- Herbs: ganoderma, licorice, astragalus, turmeric, etc.

This production line provides a one-stop solution for spice and seasoning processing, from raw material to finished product, ensuring efficiency, consistency, and hygiene in industrial-scale production.