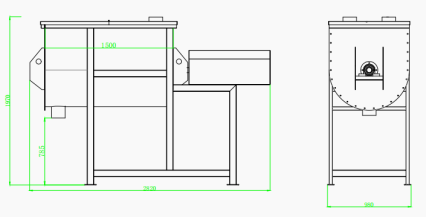

Stainless Steel Powder Mixer

1. Product Introduction

The stainless steel powder mixer is a high-efficiency and uniform mixing equipment, widely used in industries such as chemicals, food, building materials, pharmaceuticals, and feed. It is suitable for mixing powder with powder or powder with a small amount of liquid.

The equipment adopts a specially designed double-layer or multi-layer ribbon structure, which allows materials to circulate in three dimensions inside the tank, achieving fast and uniform mixing.

2. Working Principle

The ribbon mixer mainly consists of a U-shaped tank, a built-in double-layer ribbon agitator, a transmission device, and a discharge mechanism.

3. Structural Features

- Full stainless steel material (optional 304/316L), corrosion-resistant, compliant with food and pharmaceutical hygiene standards;

- U-shaped tank design with excellent sealing performance, preventing material leakage;

- Multiple discharge options: pneumatic valve or manual valve, convenient for unloading;

- Stable drive: direct connection between reducer motor and agitator, featuring low noise and low energy consumption;

- Various specifications available, with volumes ranging from 100L to 10,000L to meet different production capacities.

4. Applications

- Food industry: flour, starch, seasonings, additives, etc.

- Chemical industry: plastic powder, resin powder, dry powder coatings, etc.

- Building materials industry: dry mortar, putty powder, gypsum powder, etc.

- Pharmaceutical industry: herbal powder, pharmaceutical excipients, granules, etc.

- Feed industry: premixes, additives, vitamin powder, etc.

5. Equipment Advantages

- High mixing uniformity, up to 95% or above;

- Fast mixing speed, typically completed within 5–15 minutes;

- Low energy consumption, high efficiency, and low operating cost;

- Easy to operate and maintain, convenient to clean;

- Optional liquid spraying device for mixing powder with small amounts of liquid.