Stainless Steel Chili Crusher

The Stainless Steel Chili Crusher is a commonly used grinder in condiment processing plants, also referred to as a claw-type crusher. It is a fine grinding machine capable of achieving a fineness of up to 120 mesh, with adjustable grinding granularity. Constructed entirely from 304 stainless steel, it offers corrosion resistance, wear resistance, sturdiness, and durability. It is used to crush dry chilies into various fineness levels, such as fine powder, semi-fine, medium-coarse, and chili flakes. Different fineness levels suit different applications: fine powder is used for coloring red oil, semi-fine for barbecue seasoning, grilled meat, and barbecues, medium-coarse for oil pouring, board noodles, and stir-frying, and chili flakes or particles for making sauces, among other uses.

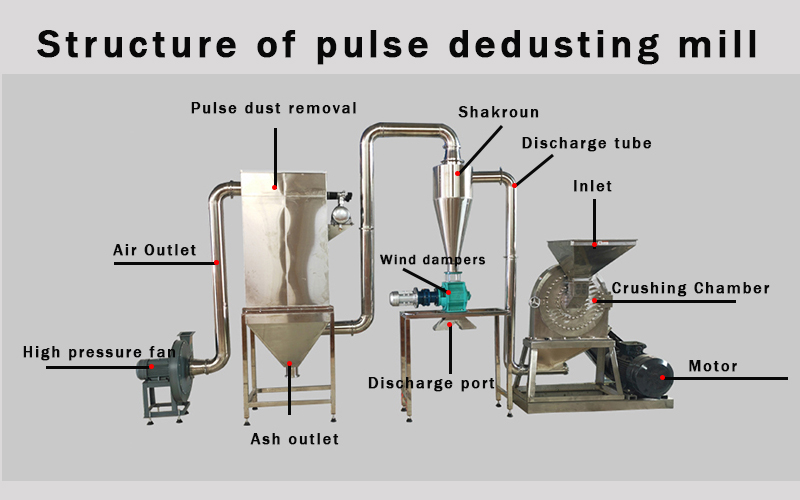

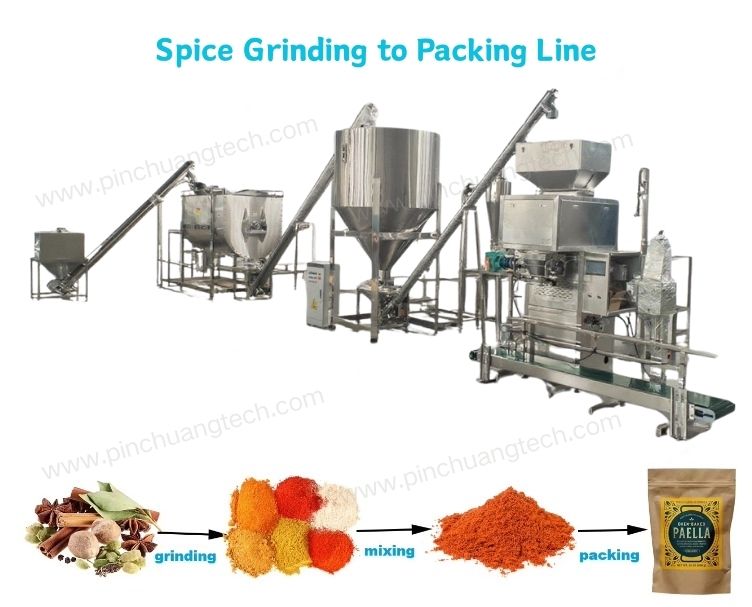

The Stainless Steel Chili Crusher is equipped with a pure copper motor, delivering strong power and high crushing efficiency. It is available in various models, allowing users to select the most suitable one based on their needs. The standalone crusher can be configured with single dust removal, double dust removal, water-cooled constant temperature, pulse dust removal, and wind-shut discharge, making it suitable for clean workshops where the production process is dust-free. It can also be integrated with mixers, elevators, and packaging machines to form a complete production line. The Stainless Steel Chili Crusher offers high productivity, low noise, easy operation, and easy cleaning.

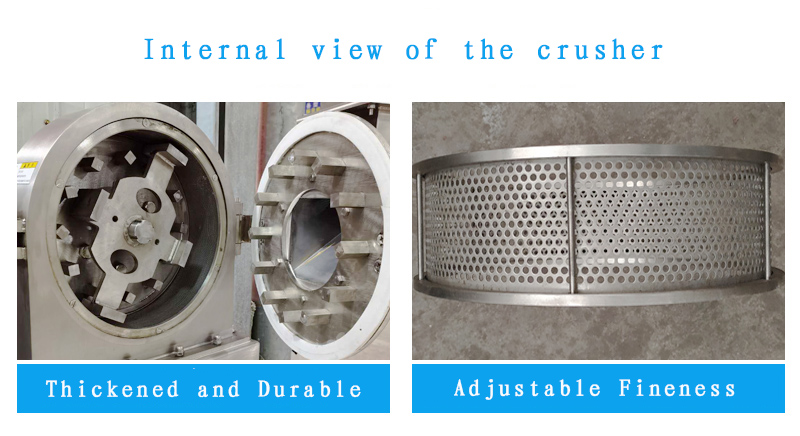

The Stainless Steel Chili Crusher utilizes fixed and movable tooth discs inside the machine to crush and grind raw materials. Its working principle involves the tooth discs rotating at high speed driven by the motor. Materials are fed evenly into the crushing chamber through the feed hopper, where the high-speed rotating tooth discs carry out the grinding process primarily through the relative grinding and impact of the upper and lower teeth on the discs. Once the desired fineness is achieved, the finished product is discharged through the screen base at the outlet. Typically, crushed materials are collected using a cotton bag, where the fine powders are retained in the bag while air escapes through the tiny pores of the bag, preventing powder waste and environmental pollution.

The Stainless Steel Chili Crusher is a versatile grinder suitable for crushing various dry and brittle raw materials, including:

- Dry chilies, chili seeds, chili stems, red chilies, Indian chilies, devil peppers

- Star anise, pepper, bay leaves, cumin, fennel, Sichuan pepper, cinnamon, bay leaves

- White sugar, rock sugar, granulated sugar, salt, sea salt

- Compound spices, barbecue seasonings, chicken stir-fry seasonings, Thirteen-Spice seasoning

- Rice, corn, starch, oats, flour, soybeans, peas, lentils, mung beans

- Spices, flavorings, sweeteners

- Dried fruits, nuts, potato chips, bread crumbs, cocoa powder, potato powder

- Coffee, milk powder, onions, dehydrated vegetables, lotus seeds, glucose, oat hulls, nut shells, ginger, oat sprouts, soybeans, etc.

The Stainless Steel Chili Crusher can be fixed on wooden frames, iron frames, or cement bases. It can also be installed on tractors or motorized tricycles, but must be securely fixed to ensure operational safety. When installing the crusher and motor, the two axes must be parallel, and the outer end faces of the two pulley wheels must be on the same plane. The motor installation should allow for adjustment clearance, and the belt tension should be properly adjusted—neither too loose nor too tight. Check if the lubricating grease in the bearings has hardened or deteriorated. If so, clean it with a suitable oil and replace it with new calcium-based grease. Also, check all bolts for looseness and tighten them if necessary. After installation, ensure there are no foreign objects inside the machine, verify that the cotter pins on the shaft are secure, close the machine cover, and tighten the handwheel. Rotate the pulley by hand to ensure smooth operation without friction or collision. Check the direction of the power machine: the motor should rotate counterclockwise. After installation, perform a no-load test to verify the correctness of the installation.