Easily Solve Spice Grinding Problems: A Reliable Helper in the Food Industry

The Claw Pulverizer offers significant advantages in the grinding field, making it suitable for the high-standard grinding requirements of the pharmaceutical, food, and chemical industries.

Its core advantages include:

- Versatile functions

- High grinding efficiency

- Adjustable fineness

- Simple and compact structure

- Strong adaptability

Key Features

1. Versatility

Capable of grinding a wide range of materials such as grains, spices, herbal medicine, and coarse cereals, meeting the needs of various industries and users.

- In agriculture: it can grind corn, wheat, and other grains for feed processing.

- In traditional medicine: it can grind different herbs to meet formulation requirements.

2. High Efficiency

The claw structure is uniquely designed. When operating, the claws rotate at high speed, applying strong impact, shear, and friction forces to materials. This ensures rapid grinding and enables large batches to be processed in a short time, greatly improving production efficiency.

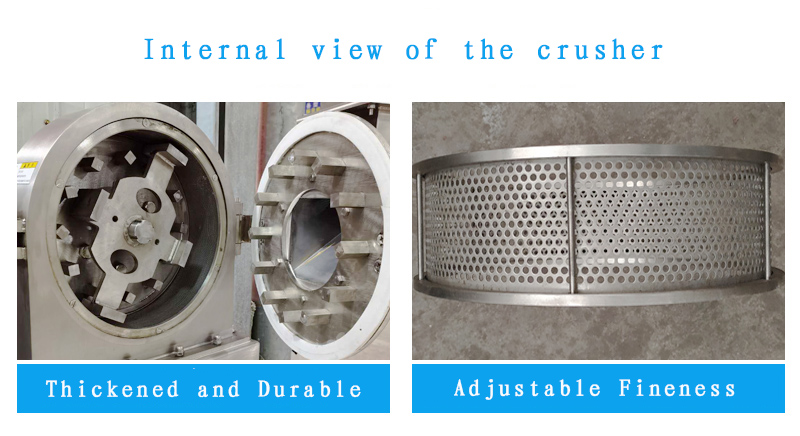

3. Adjustable Fineness

By adjusting the sieve aperture size and claw gap, different fineness levels can be achieved, from coarse to fine powder.

For example, in feed production, fineness can be adjusted based on animal type and growth stage.

4. Simple and Compact Structure

The overall structure is relatively simple, mainly consisting of the motor, grinding chamber, claws, and sieve.

It occupies little space, is easy to install and maintain, and reduces installation costs and maintenance difficulty, making it user-friendly.

5. Strong Adaptability

The machine can be integrated with various feeding, discharging, and subsequent processing equipment to form an automated production line.

This improves automation and overall efficiency, ensuring stable performance in diverse production scenarios.

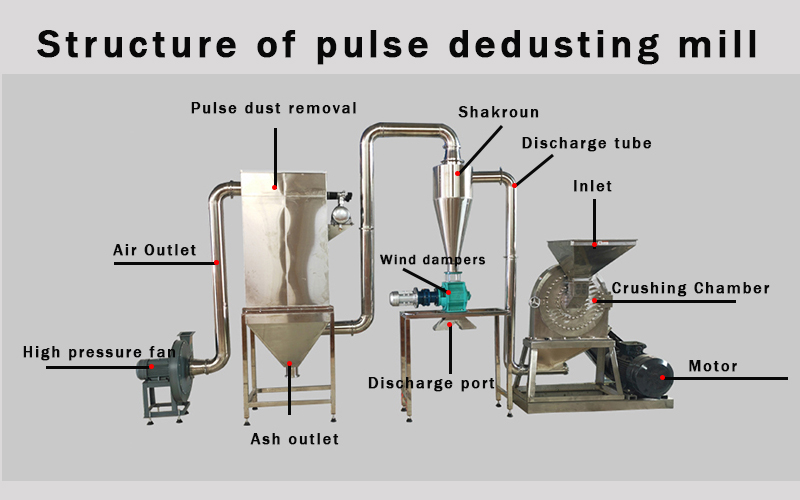

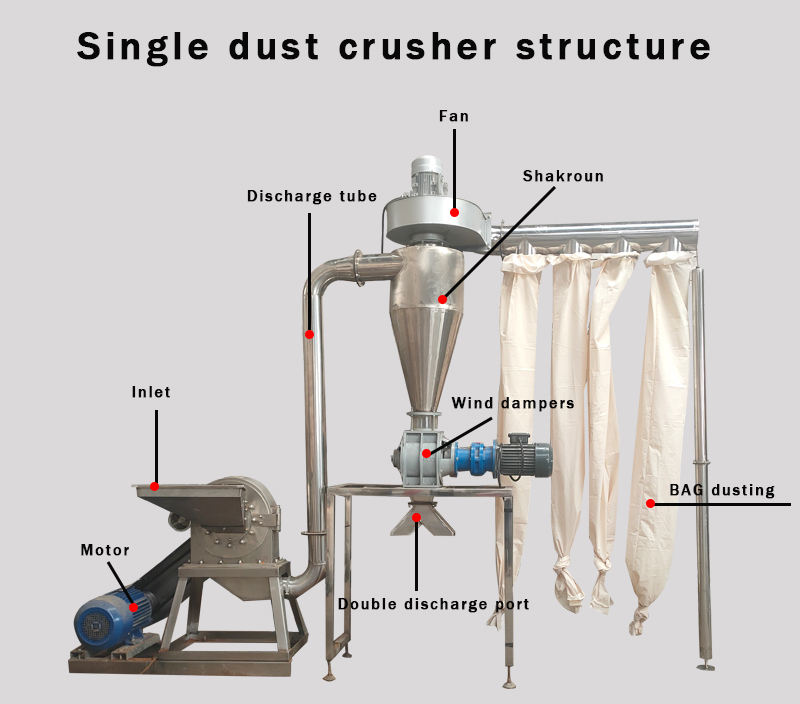

Grinding Production Line Workflow

Step 1:

The operator starts the pulverizer. Raw materials enter the machine through the feed inlet.

The claws and other grinding components rotate at high speed, crushing the material through impact, shear, and friction.

During grinding, a large amount of dust-laden air is generated and discharged from the pulverizer’s exhaust outlet into the dust removal system.

Step 2:

Driven by the negative pressure generated by the fan, the dusty air is transported through pipelines to the pulse dust collector.

The fan provides continuous and stable power, ensuring the dusty air can overcome pipeline resistance and flow smoothly into the dust collector for further treatment.

Step 3:

Inside the pulse dust collector, the dusty air enters a chamber equipped with filter bags.

Dust particles are trapped on the surface of the filter bags, while clean air passes through into the clean air chamber and exits from the outlet.

As dust accumulates, resistance increases. Once the set limit is reached, the pulse jet system activates.

Compressed air is injected through pulse valves into the filter bags, causing them to expand instantly and shake off the dust layer into the hopper.

The collected dust in the hopper is discharged regularly via the ash removal device, completing the dust collection and processing cycle.