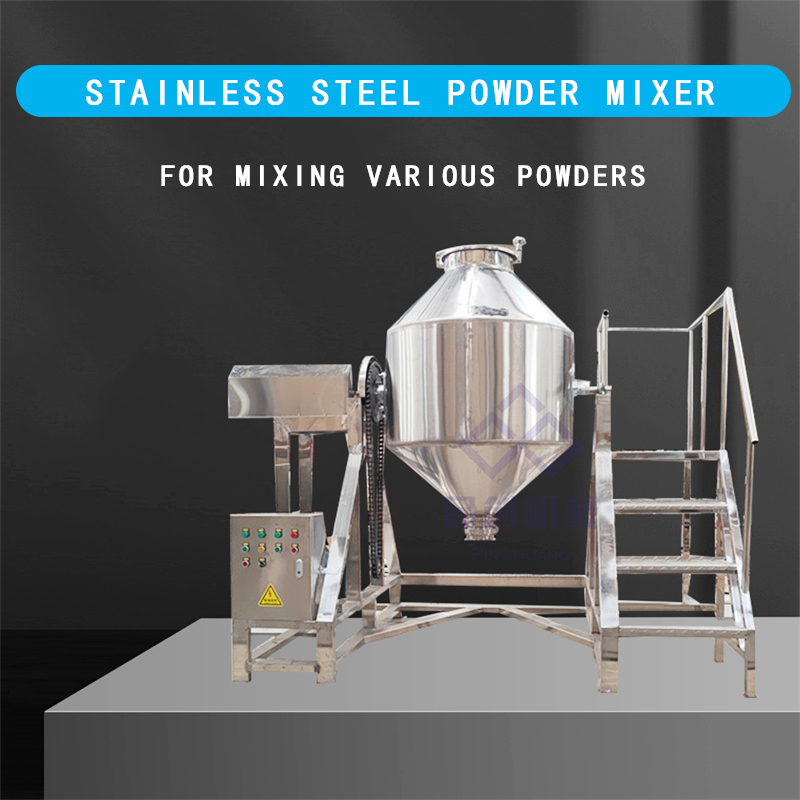

Stainless Steel Powder Mixer

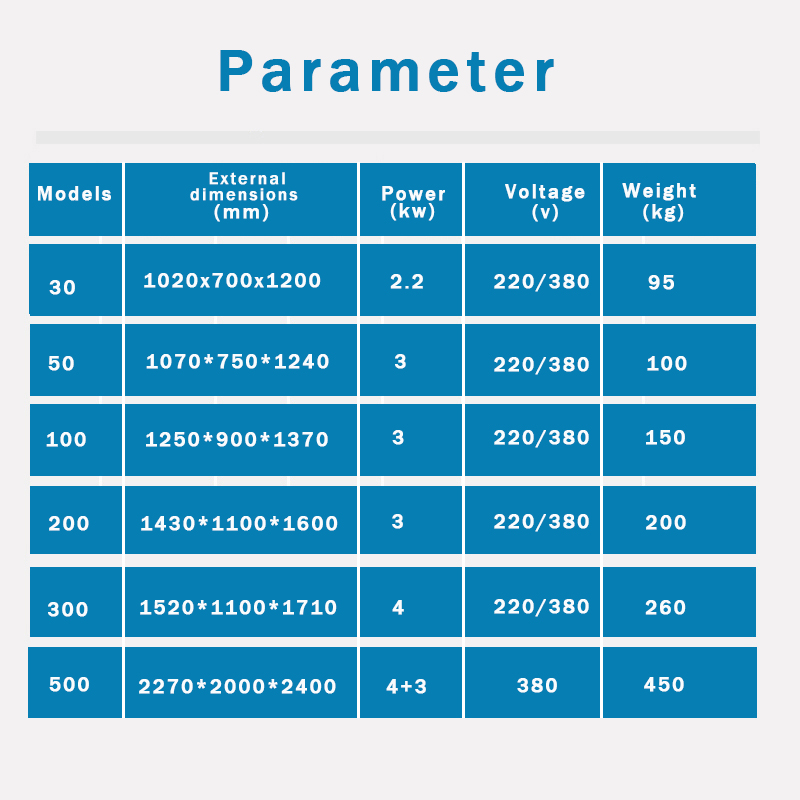

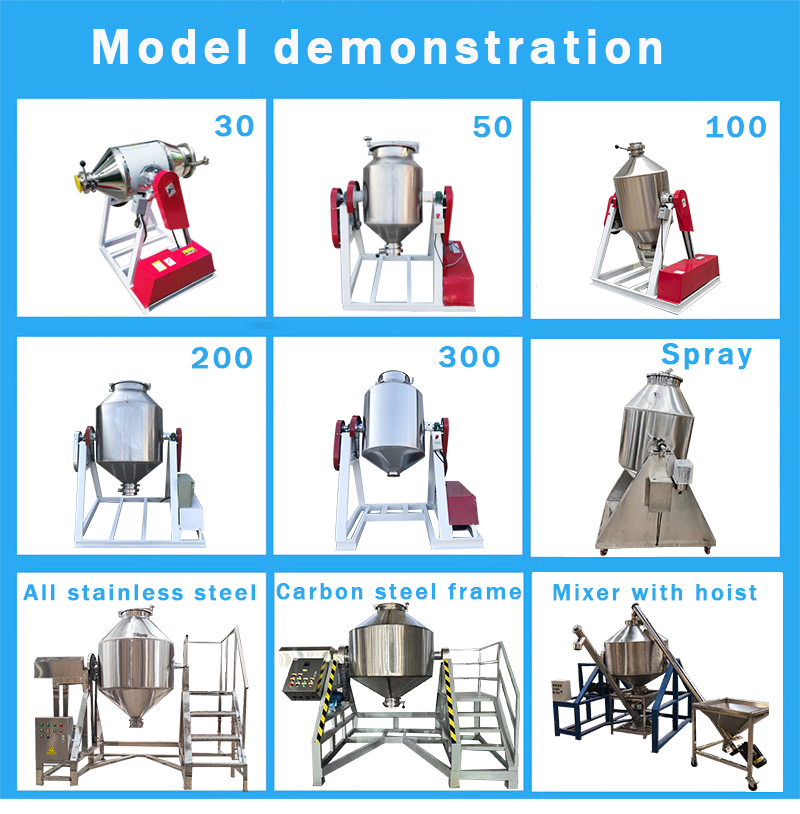

The stainless steel powder mixer is a small powder mixing machine used for blending various types of powders. It is constructed from stainless steel, with options for 201, 304, or 316 grades based on requirements. This mixer features 360-degree rotation, capable of both forward and reverse directions, and is designed as a double cone mixer. Equipped with internal blades, it ensures a more uniform mixture of powder materials. Available models include 10L, 18L, 50, 100, 200, 300, and 500 types.

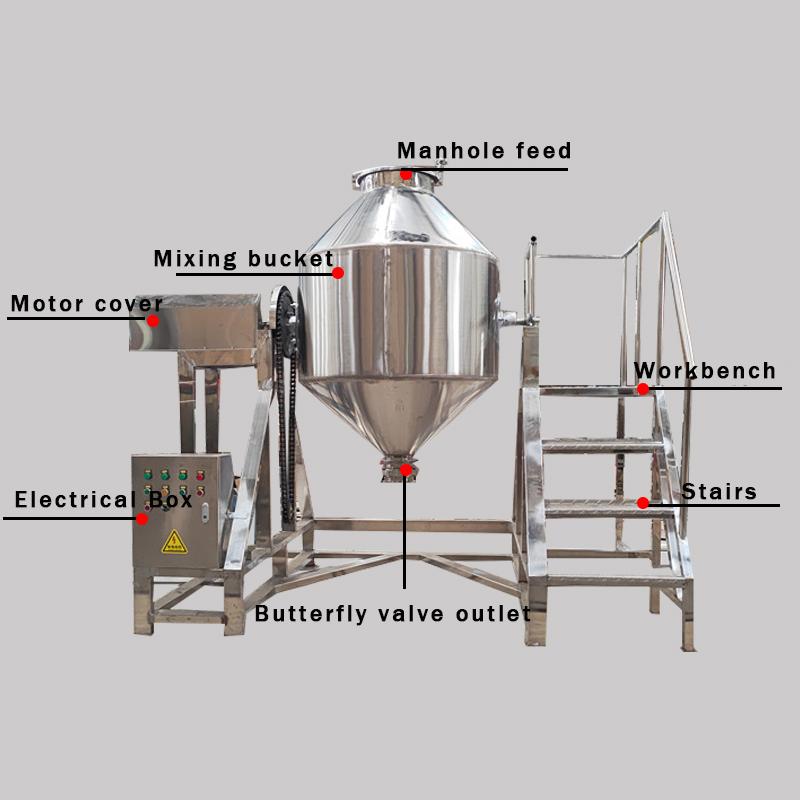

During operation, the mixing blades rotate while the double cone tumbles, causing the materials inside to tumble and mix chaotically. The high-speed rotating blades break up agglomerates, enabling rapid mixing within the drum. It features a manhole for feeding and a butterfly valve for discharge. The butterfly valve provides a tight seal and allows control over the discharge rate. It is suitable for mixing free-flowing powders and achieves good mixing uniformity even with minor additive components. The machine uses mechanical seals to prevent powder leakage and has a long bearing service life. It requires low labor intensity and is easy to operate.

How to Select a Stainless Steel Powder Mixer Material Characteristics First consider the properties of the material (particle size, density, viscosity, corrosiveness), the required mixing uniformity, and production capacity requirements.Capacity Selection Choose the appropriate working capacity based on batch output and material density requirements. Avoid underpowering the machine for the task.Power Source Electric drive for fixed sites; diesel engine drive for mobile operations or areas without electricity.Material Requirements**: Select stainless steel or other special steels for parts contacting the material based on its corrosiveness.

Applicable Powders for Mixing The stainless steel powder mixer can blend:

Flour, rice flour Sugar, salt, seasoning powders Blended chili powder, cumin powder, five-spice powder, curry powder, pepper powder, star anise powder Grain powders, vitamins, food additives (e.g., dough strengtheners, bleaching agents)

Milk powder, powdered sugar, coffee powder, cocoa powder, milk tea powder, glucose powder Instant beverage powders, tea powder Pre-mixed powders for cakes, bread, biscuits Starch, lactose, microcrystalline cellulose Pigments, dyes Chemical powders, industrial salt Feed additives, mineral powders Sea salt, bath salt, and other powders.

Usage and Maintenance Notes

- No-load Start: Never start the machine under load. Start the motor first, then feed materials gradually.

- Even Feeding: Feed materials in the specified order and at the recommended speed. Avoid overloading or feeding too quickly at once to prevent jamming (stalling).

- Regular Cleaning: Clean residual material from inside and outside the mixer after each shift to prevent hardening and clumping, which could affect future use and equipment balance.

- Regular Inspection: Regularly check the blades for wear. Replace them promptly if excessively worn to maintain mixing efficiency. Also, check the lubrication system to ensure all rotating parts are well-lubricated.

- Safety During Operation: Never insert hands or tools into the drum while the equipment is running. Always disconnect power and hang a warning sign during maintenance.