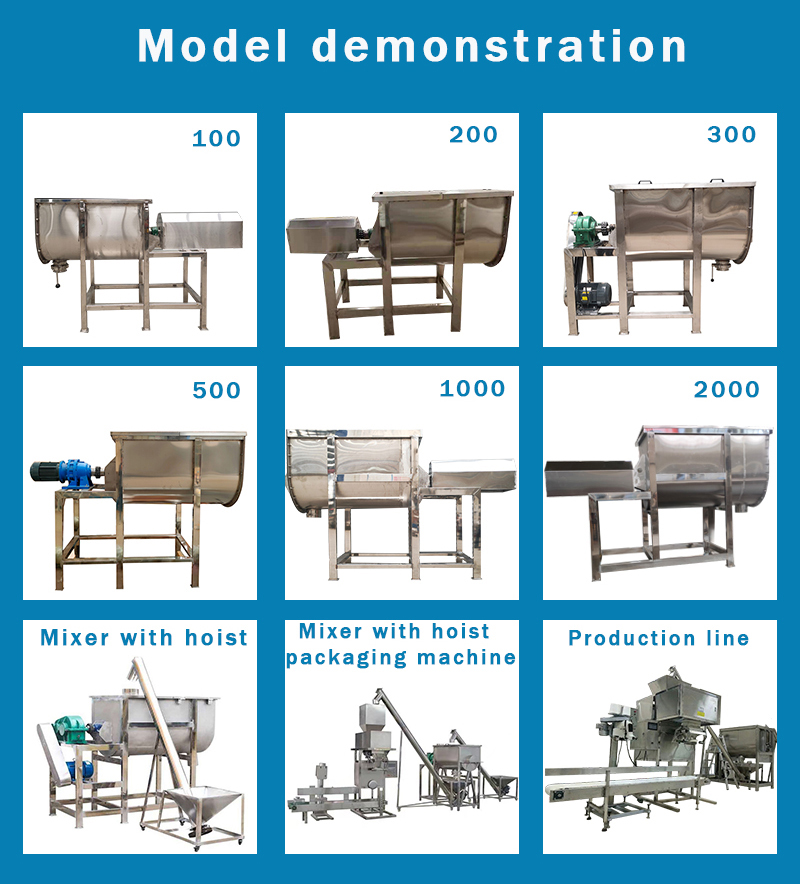

Stainless Steel Food Powder Mixer

The stainless steel food powder mixer is a specialized mixing machine designed for blending powdered raw materials. It is a ribbon-type powder mixer, also referred to as a U-type stainless steel mixer. As the name suggests, it features a U-shaped horizontal structure for the mixing container (barrel). The entire machine is made of 304 stainless steel, offers powerful performance, and can thoroughly mix various raw materials evenly.

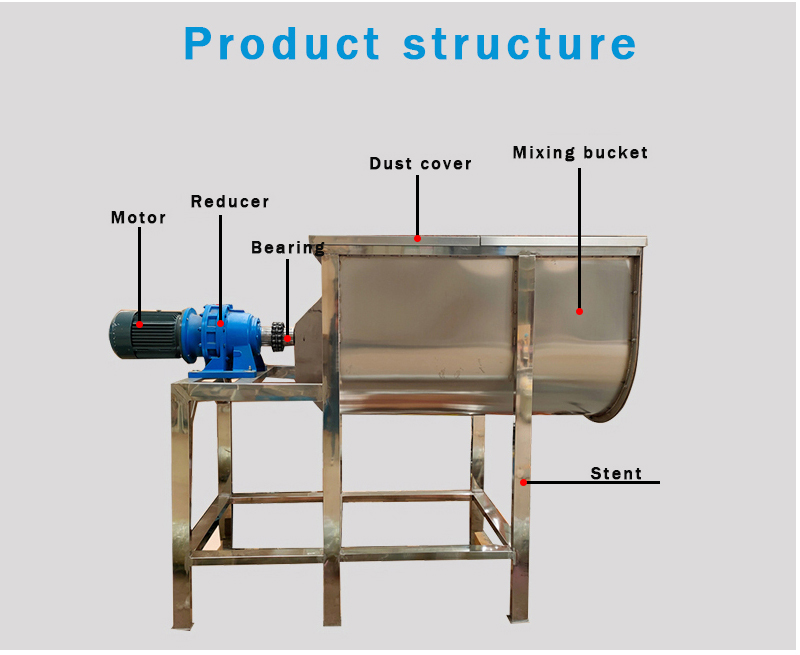

The core components of the stainless steel food powder mixer include:

- U-shaped Mixing Trough: The main body of the equipment. Its U-shaped bottom design is dead-angle-free, enabling materials to form a good convective circulation during mixing, ensuring uniform blending.

- Mixing Blades: The core working parts installed on the mixing shaft. It features a three-layer ribbon with wall scrapers attached, ensuring a cleaner discharge with minimal residue.

- Transmission System: Includes the motor, reducer, etc., providing stable power to the mixing shaft and controlling the mixing speed and torque.

- Frame and Sealing Device: Supports the entire equipment and ensures the sealing at the connection between the mixing shaft and the barrel, preventing material leakage and contamination.

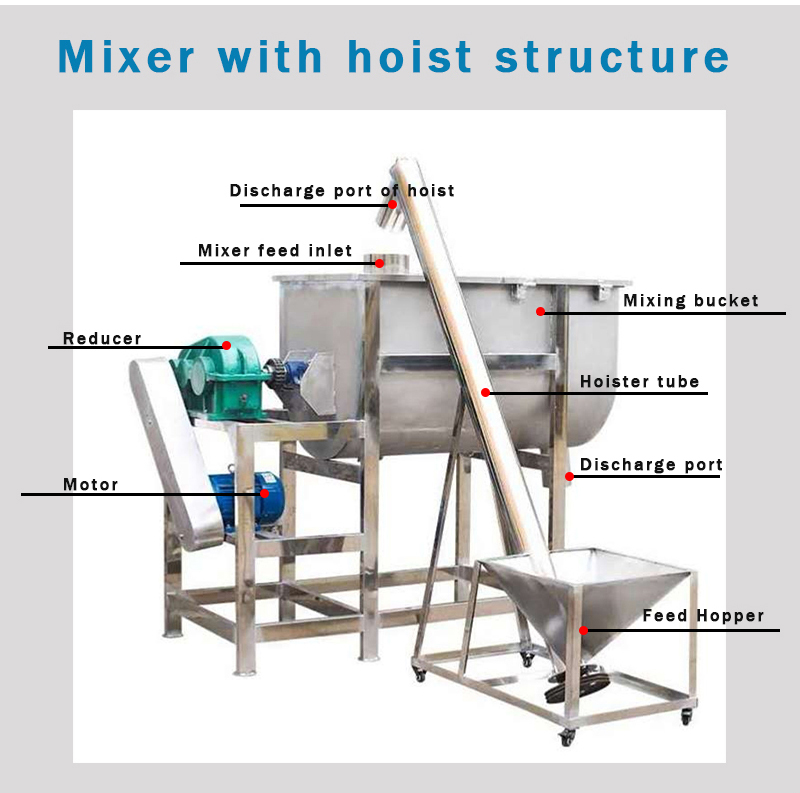

When using the stainless steel food powder mixer, start the mixer first before adding materials into it. This practice helps extend the mixer’s service life. The mixer is equipped with a dust cover to prevent dust generation during the mixing process. The dust cover is typically designed as a half-open lid for easy addition of materials or observation of the mixing status. A sealing strip is fitted around the mixer’s border to prevent dust from leaking. This crusher can also be equipped with a spray function as needed, allowing for liquid spraying while mixing. This helps prevent dust generation and enables both dry and wet uses (i.e., adding a small amount of liquid). A staircase work platform can also be equipped for manual feeding or for use with a stainless steel screw conveyor for feeding.

The stainless steel food powder mixer features inner, middle, and outer spiral blades. During operation, the inner and outer spirals drive the material turnover inside the cylinder. The inner spiral drives the material near the axis to rotate axially, pushing from the inside to both sides and moving the material towards the cylinder wall. The outer spiral drives the material near the cylinder wall to rotate axially, pushing from both sides inward and gathering the material towards the center. This allows the ribbon agitator to turnover materials across a wide range inside the cylinder. Materials undergo convective circulation, shear, and permeation mixing inside the cylinder, achieving uniform mixing in a short time. Generally, one mixing cycle takes 5 to 10 minutes, depending on the amount of raw material. Discharge is carried out using a butterfly valve, which provides tight sealing and allows for controllable discharge speed.

The stainless steel food powder mixer can mix and blend various raw materials such as:

Flour, rice flour, starch, bread crumbs, wheat flour, sugar, salt, monosodium glutamate (MSG), chicken bouillon powder, chili powder, chili flakes, chili granules, pepper powder, star anise powder, cinnamon powder, cumin powder, five-spice powder, white cardamom, clove powder, curry powder, cocoa powder, milk tea powder, coffee powder, glucose powder, fruit and vegetable powder, baking soda, meal replacement powder, pigments, chemical powders, metal powders, pharmaceutical powders, etc.