Multi-Purpose Cocoa Bean Grinder

(Also suitable for coffee beans and nuts)

I. Product Introduction

The cocoa bean grinder is a specialized machine designed to grind roasted cocoa beans into cocoa liquor, a key step in chocolate production. This machine effectively breaks down the cellular structure of cocoa beans, releasing cocoa butter and cocoa solids. The resulting cocoa liquor is smooth and uniform, serving as an essential raw material for chocolate, cocoa powder, and other cocoa-based products.

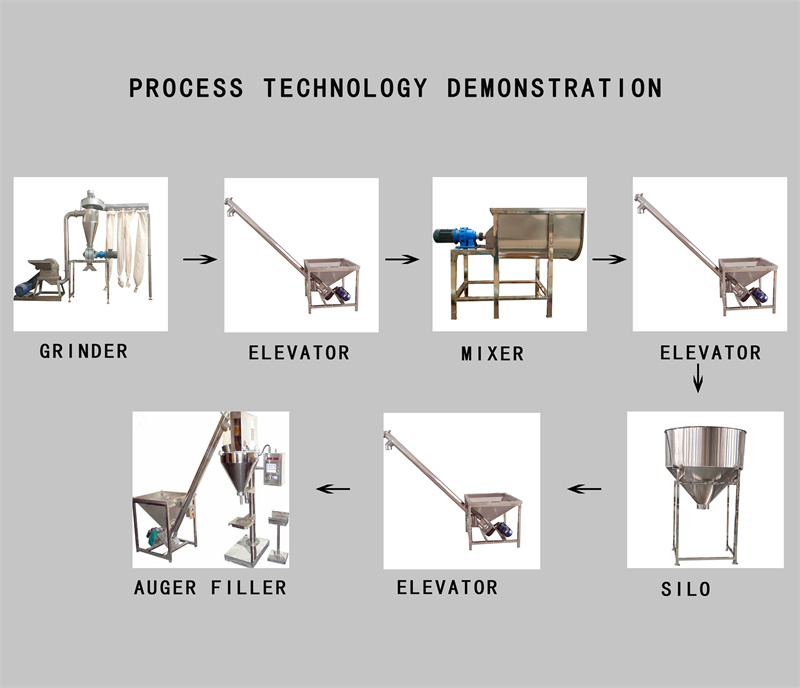

II. Working Principle

The grinder uses high-speed rotating grinding plates, rollers, or stone mills to crush, shear, and grind roasted cocoa nibs:

- Primary Grinding: Cocoa nibs are broken down into coarse particles.

- Fine Grinding: Particles are gradually refined under pressure and friction, releasing cocoa butter.

- Homogenizing: Produces a uniform, smooth cocoa liquor suitable for chocolate production.

Some models are equipped with a circulating cooling system to prevent overheating during grinding, which helps preserve the natural cocoa aroma.

III. Structural Features

- Full Stainless Steel Design: Food-grade, corrosion-resistant, and easy to clean.

- High Grinding Fineness: Adjustable from 10–120 mesh, meeting chocolate industry standards.

- Low-Temperature Grinding: Prevents flavor loss caused by excessive heat.

- High Efficiency: Fast grinding with stable output.

- Automated Control: Some models feature intelligent controls for easy operation.

- Customizable Capacity: From small lab-scale units to large industrial production models.

IV. Applications

- Chocolate Manufacturers: For primary and fine grinding of cocoa liquor.

- Food Processing Plants: For producing cocoa powder, cocoa paste, and cocoa-based beverages.

- Laboratories / R&D Centers: For small-batch testing and product development.

- Artisanal Chocolate Workshops: Small-scale cocoa grinding equipment for handcrafted chocolate.

V. Advantages

- Smooth Grinding: Ensures fine cocoa liquor texture, improving chocolate mouthfeel.

- Flavor Retention: Low-temperature processing preserves natural cocoa aroma.

- High Efficiency & Stability: Suitable for continuous production.

- Easy Cleaning: Smart structural design reduces material residue.

- Customizable Solutions: Adaptable to different production capacities and needs.