Coffee Powder Mixer – The Ideal Equipment for Fast and Uniform Coffee Powder Blending

1. Product Introduction

The coffee powder mixer is designed for evenly blending different formulas of coffee powder, creamer, milk powder, sugar powder, and other additives.

Made of food-grade stainless steel, the machine meets hygiene standards and ensures fast and efficient powder mixing, guaranteeing product flavor consistency.

It is widely used in coffee processing plants, beverage manufacturers, instant coffee production lines, and the food seasoning industry.

2. Working Principle

The coffee powder mixer typically adopts either ribbon mixing or drum mixing:

- Ribbon Type: Inner and outer ribbons move materials in opposite directions, achieving fast and uniform mixing.

- Drum Type: The rotating drum causes powders to tumble, diffuse, and convect—ideal for gentle mixing of lightweight powders.

Through 3D circulation and shearing effects, powders reach the desired uniformity within a short time.

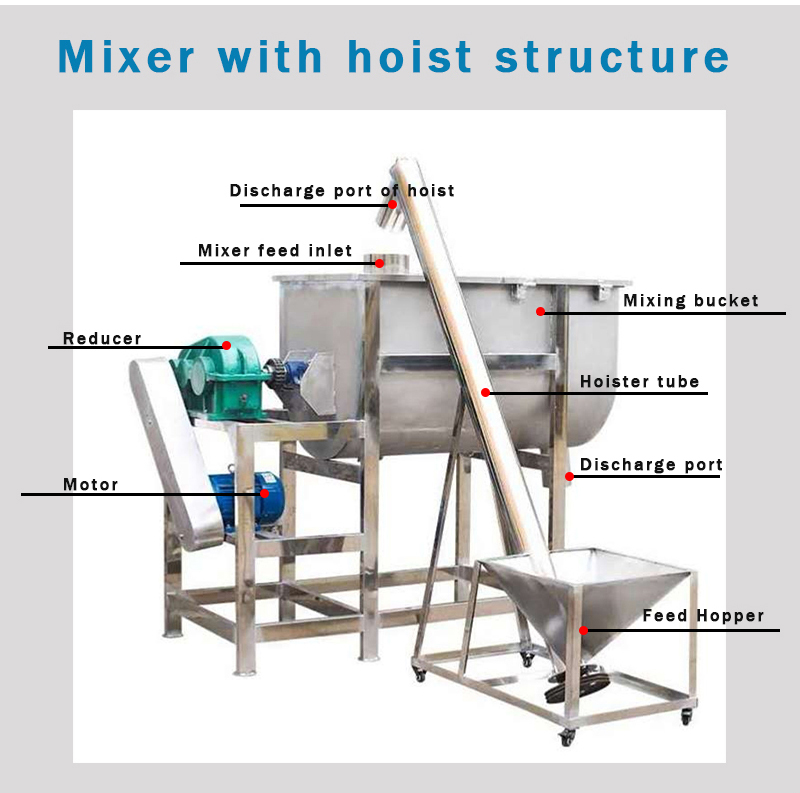

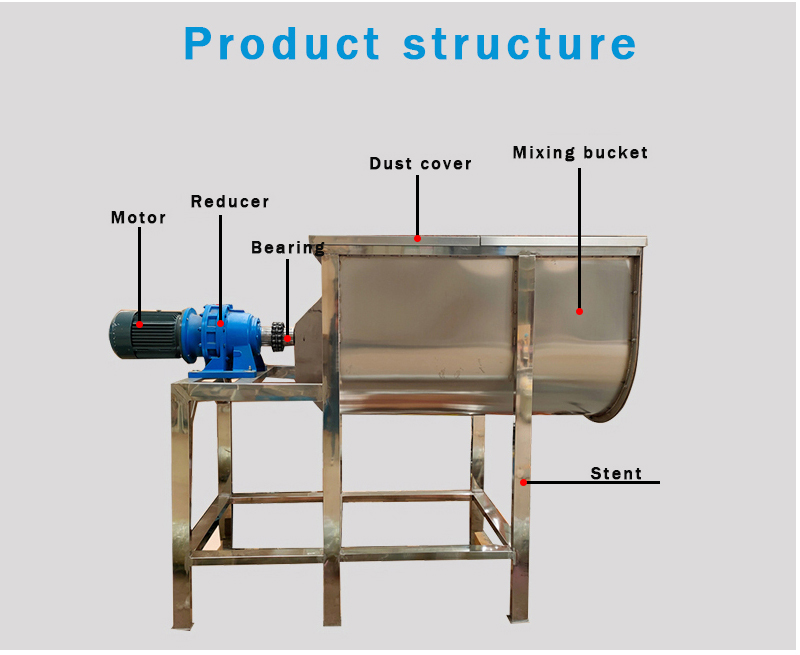

3. Structural Features

- Full stainless steel construction: optional 304/316L, safe, hygienic, and corrosion-resistant;

- High mixing uniformity: up to 95% or more;

- Easy operation: simple electric control system with one-button start;

- Multiple discharge options: manual or pneumatic valves for quick and complete discharge;

- Optional liquid-spraying system: allows mixing coffee powder with small amounts of flavoring or oils;

- Easy-to-clean design: convenient disassembly, ideal for frequent recipe changes.

4. Applications

- Coffee Industry: instant coffee powder, 3-in-1 coffee, cold brew coffee powder;

- Beverage Industry: milk tea powder, cocoa powder, solid drink formulas;

- Food Industry: seasoning powder, nutrition powder, protein powder;

- Health Products: compound nutritional powders, meal replacement powders.

5. Equipment Advantages

- Fast mixing: one batch completed in 5–15 minutes;

- Consistent taste: ensures stable coffee flavor in every batch;

- Gentle mixing: preserves powder properties without damage;

- Flexible capacity: available from tens of liters to several thousand liters, customizable to production needs.