Efficient Grain Grinder – Easy Milling of Cereals

1. Product Introduction

The grain grinder is a specialized machine designed to crush various cereal crops (such as wheat, corn, rice, oats, sorghum, etc.) into fine powder or coarse granules. The equipment adopts high-speed rotating hammers, discs, or blades to apply impact and shearing forces, enabling fast and efficient grinding. It is widely used in food processing, feed production, pharmaceuticals, healthcare products, and the chemical industry.

2. Working Principle

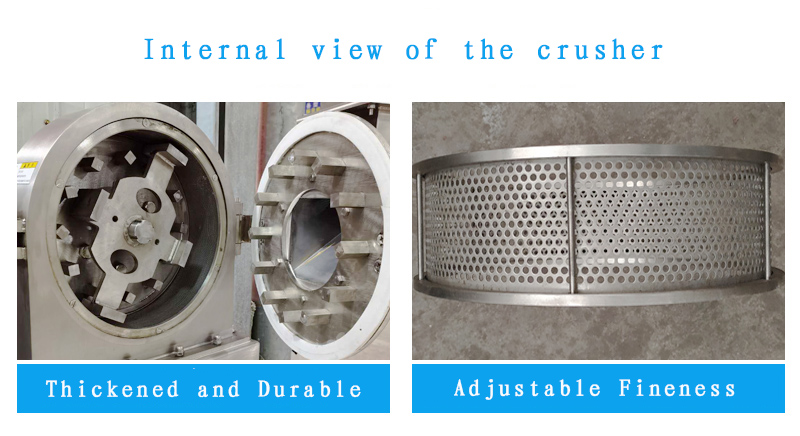

The grain grinder consists of a feeding inlet, grinding chamber, blades/hammers/claws, screen, and discharge outlet:

- Motor drive: The motor drives the blades or hammers to rotate at high speed;

- Impact grinding: Grains are subjected to impact, shear, and friction inside the chamber;

- Screening: The ground particles are discharged through a screen, with mesh sizes controlling the particle fineness.

3. Structural Features

- Optional stainless steel construction: Food-grade, wear-resistant, and corrosion-resistant;

- High grinding efficiency: Strong motor power allows grinding in just a few seconds;

- Adjustable particle size: By replacing the screen or adjusting the rotation speed, different levels of fineness can be achieved;

- Good sealing performance: Prevents dust leakage and keeps the workshop clean;

- Compact design: Small footprint, easy operation, and convenient maintenance;

- Safety device: Overload protection ensures safe operation.

4. Applications

- Food industry: Rice flour, corn flour, wheat flour, multi-grain flour;

- Feed industry: Feed raw material grinding, premix processing;

- Pharmaceutical industry: Herbal medicine and plant grinding;

- Healthcare products: Meal replacement powders, nutritional powders;

- Chemical industry: Dry powder materials, light powders.

5. Equipment Advantages

- High fineness: Adjustable from 20–120 mesh, some models capable of ultra-fine powder;

- Wide applicability: Suitable for hard, brittle, and partially fibrous materials;

- High efficiency & low energy consumption: Economical and practical;

- Easy cleaning: Quick disassembly reduces material residue;

- Customizable: Different models available according to capacity and material characteristics.