Laundry Detergent Powder Production Line

What Equipment is Required for a Laundry Powder Production Line?

Laundry powder is widely used in daily life. So, what equipment is needed to produce laundry powder?

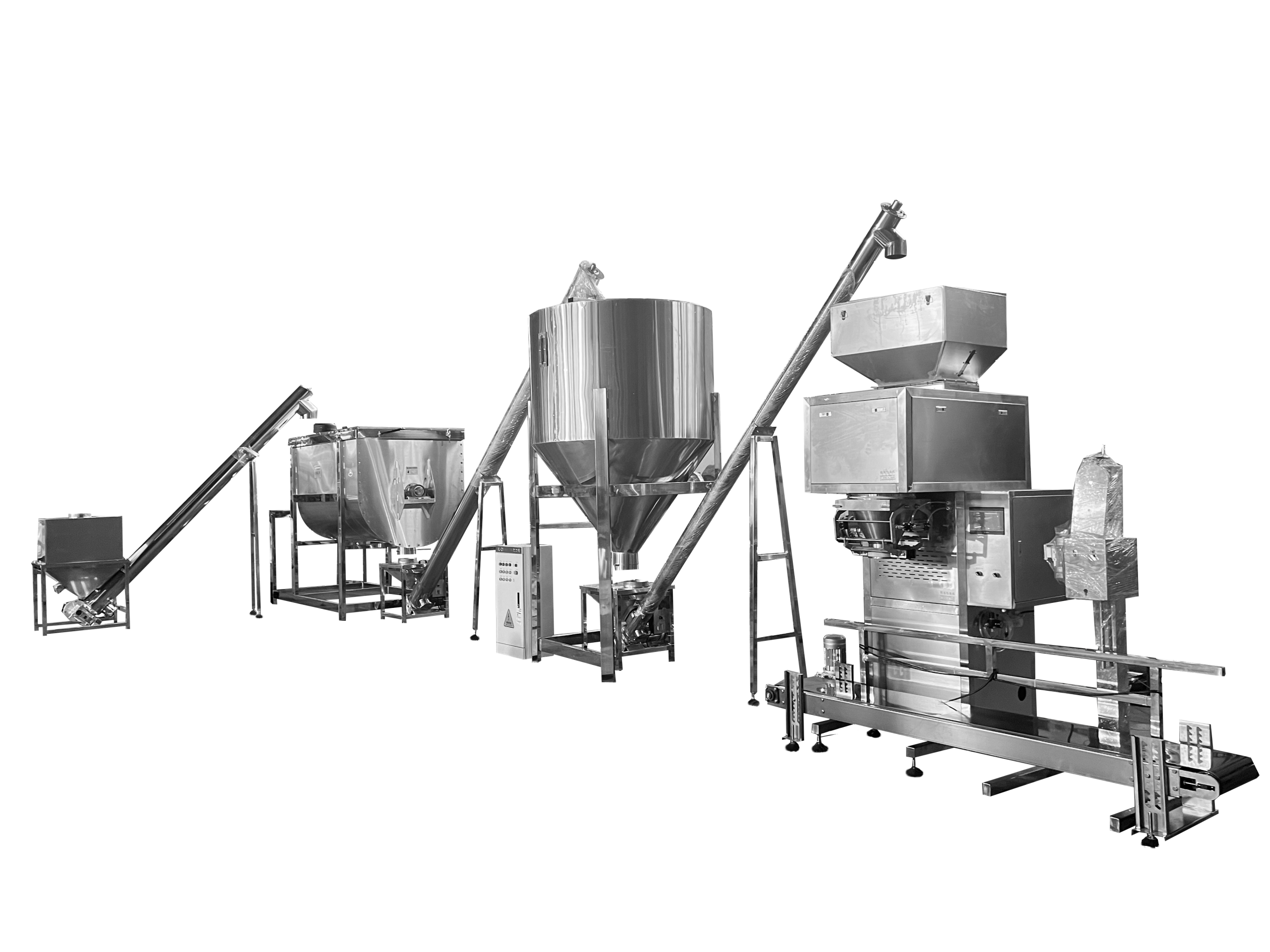

A complete laundry powder production line typically includes:

- Screw Conveyor

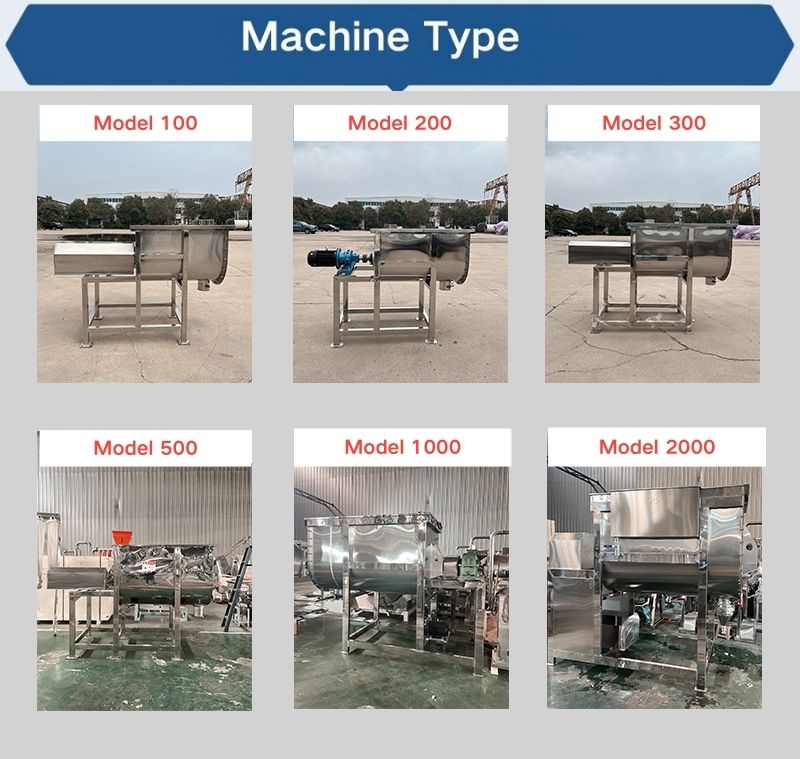

- U-Type Ribbon Mixer

- Screw Conveyor

- Storage Silo

- Screw Conveyor

- Open Bag Packaging Machine

Laundry Powder Mixing Process

Step 1:

Workers start the screw conveyor and sequentially pour various raw materials of laundry powder into it.

Driven by the motor, the screw conveyor transports the powder raw materials into the mixer tank.

Step 2:

After the powder has been conveyed, the mixer is started.

The powder is stirred and heated while atomized essence is sprayed into the mixer through nozzles, achieving uniform mixing and fragrance addition.

Step 3:

Once mixing is complete, the mixer discharges by reversing.

The outlet connects to a screw conveyor, which transports the unclumped materials into the storage silo.

Step 4:

The materials in the storage silo are conveyed by a screw conveyor into the packaging machine.

Step 5:

The finished product is packed and sealed by the packaging machine.

Advantages of the Laundry Powder Mixing Production Line

1. High Mixing Uniformity

The ribbon mixer has a triple-layer ribbon inside the tank.

It stirs gently without damaging materials, achieving excellent mixing results.

It ensures materials tumble in all directions for uniform blending, and is also suitable for sticky materials.

When combined with a reactor, it can spray liquid, ensuring mixing quality.

2. Sealed Production Without Dust

The screw conveyor adopts a fully enclosed design, preventing dust during transportation.

The discharge port and drum inlet are connected with soft joints, providing flexibility, convenience, and good sealing.

The packaging machine’s silo is covered with a lid, preventing dust leakage during discharge.

Overall, the production process operates without dust emission.

3. Efficient Production

The drum mixing production line enables continuous operation across multiple machines,

quickly completing raw material conveying, mixing, fragrance addition, and packaging.

This greatly improves the output of laundry powder per unit time, with significantly higher efficiency compared to manual operations.

4. Wide Applications

The drum mixer is suitable for materials of different properties such as powders, granules, lumps, or strips.

It can handle both dry materials and moist materials containing some water content, ensuring effective mixing in all cases.