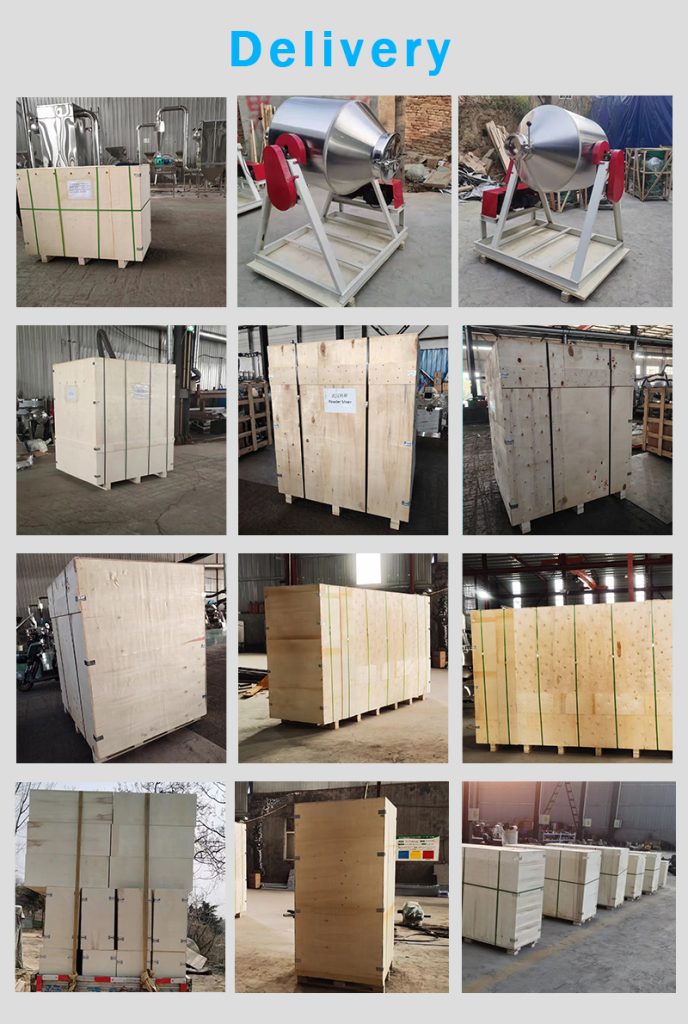

Powder Mixing Machine

1. Product Introduction

The stainless steel drum-type powder mixing machine is a high-efficiency and gentle powder mixing equipment, mainly used for the uniform mixing of various powders or granular materials. The equipment is made of high-quality stainless steel, featuring corrosion resistance, easy cleaning, and compliance with food and pharmaceutical hygiene standards. It is widely used in the food, pharmaceutical, chemical, healthcare, and building materials industries.

2. Working Principle

The drum mixer rotates the barrel to make the powder materials inside continuously tumble, diffuse, and convect. In three-dimensional space, the materials repeatedly intersect, stack, and disperse, thus achieving uniform mixing. With built-in stirring paddles, the equipment provides gentle mixing without damaging particle integrity, making it especially suitable for lightweight, fragile, or integrity-required materials.

3. Structural Features

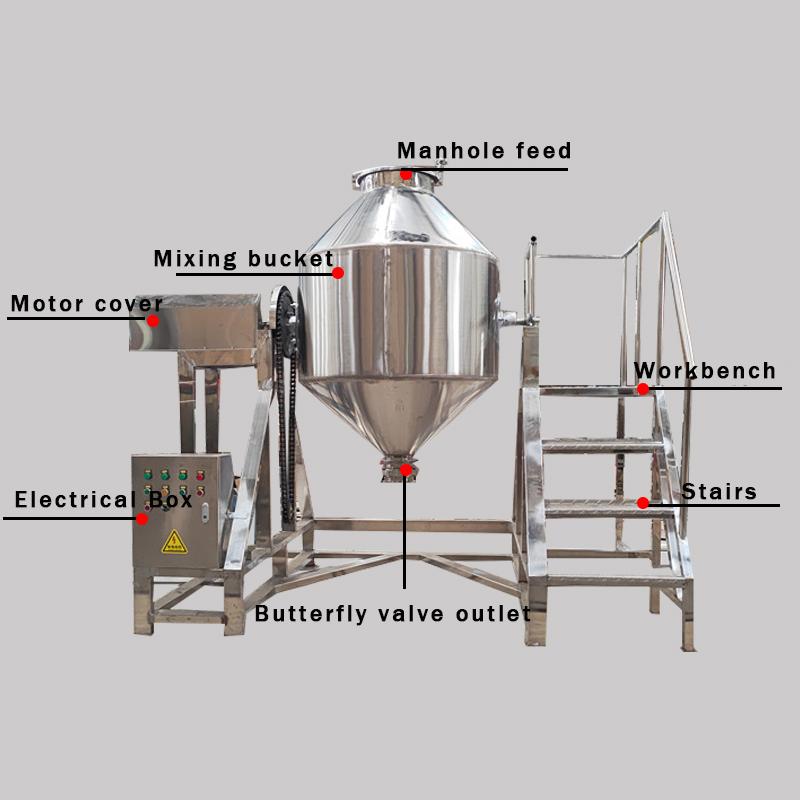

- All Stainless Steel Construction: Optional 304/316L, strong and durable;

- Simple Drum Design: 360° rotation with no dead angles, minimal material residue, easy to clean;

- Excellent Sealing: Manhole feeding port and butterfly valve discharge port, preventing dust leakage and ensuring a clean working environment;

- Easy Operation: Convenient feeding and discharging, simple and reliable control system, forward and reverse rotation available;

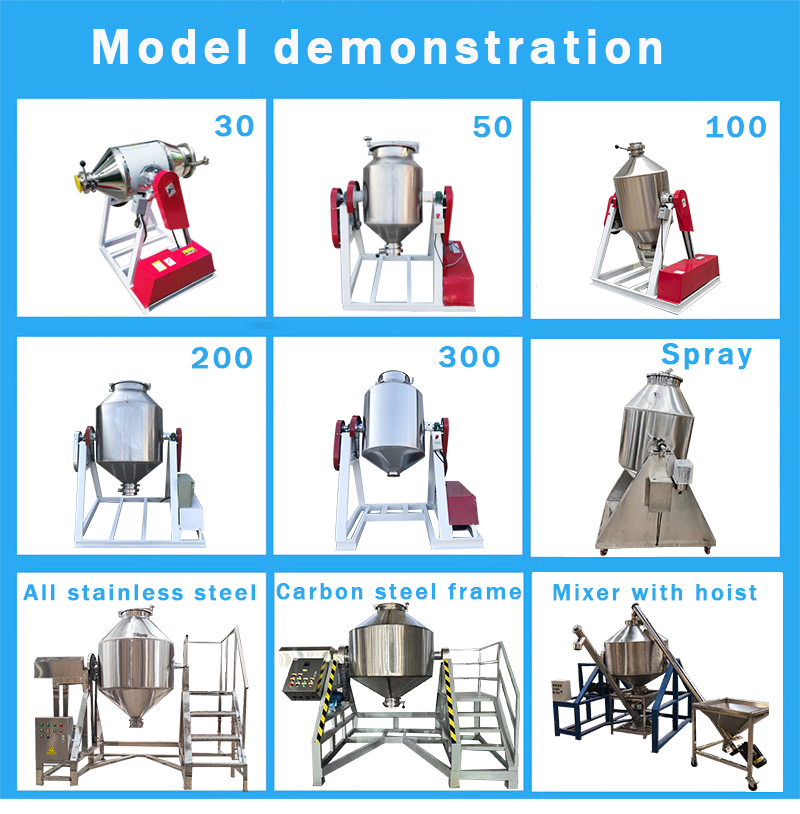

- Multiple Specifications: Customizable capacity from 30KG to 1000KG to meet production needs.

4. Application Scope

- Food Industry: Milk powder, protein powder, seasoning powder, beverage powder, etc.;

- Pharmaceutical Industry: Herbal powder, granules, excipients mixing;

- Healthcare Industry: Nutritional powder, meal replacement powder, compound additives;

- Chemical Industry: Resin powder, dry additives, lightweight chemical powders;

- Building Materials Industry: Lightweight powder, putty powder, gypsum powder, etc.

5. Equipment Advantages

- High mixing uniformity, suitable for industries with strict formulation requirements;

- Gentle mixing without damaging materials, maintaining particle integrity and powder properties;

- Low energy consumption, high efficiency, economical and practical;

- Easy to clean, quick switching between different materials;

- Mobile and convenient, compact design with anti-slip caster wheels.