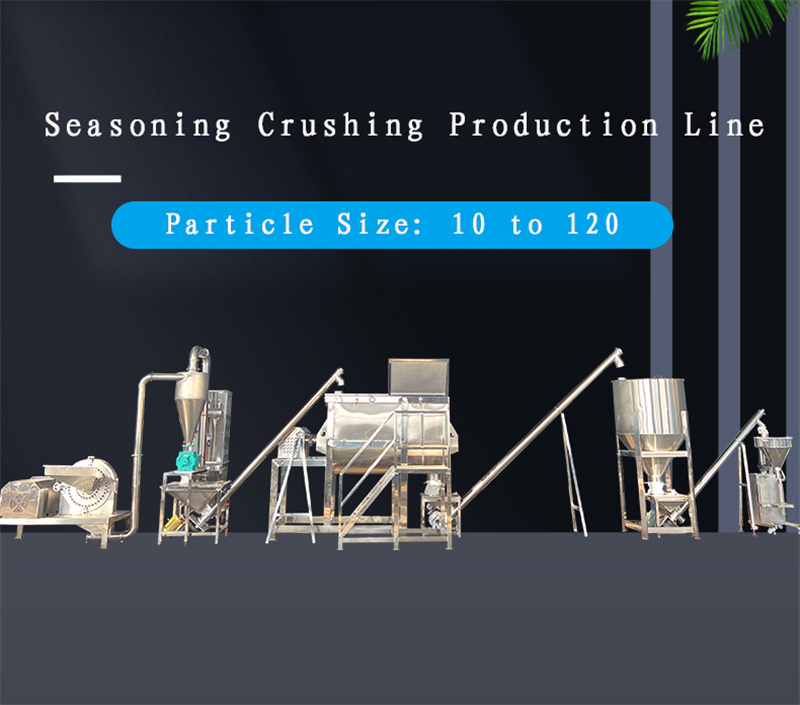

Seasoning Crushing Production Line

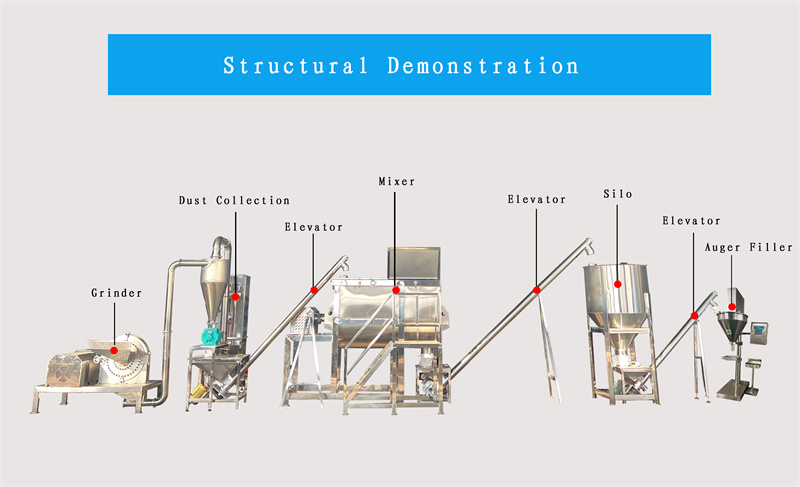

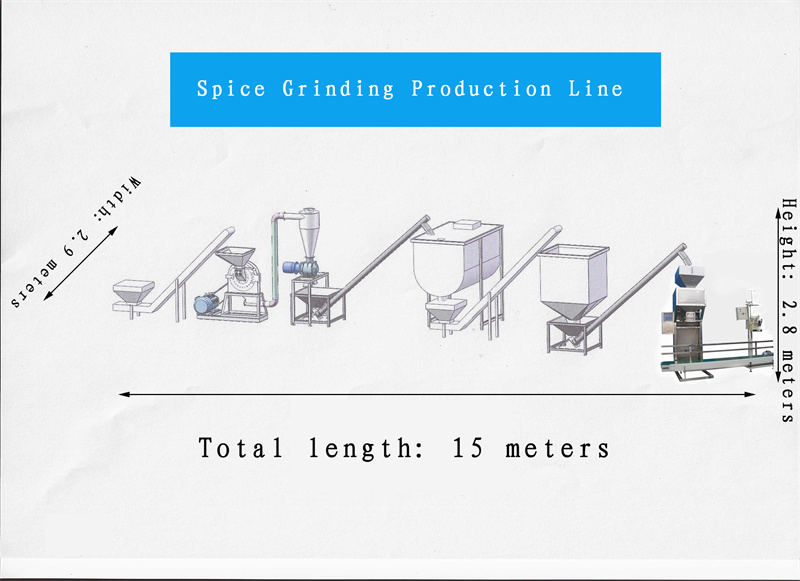

The seasoning crushing production line refers to a complete set of equipment for crushing — elevating — mixing — packaging seasonings. This production line uses various spices as raw materials, which are processed through crushing, screening, mixing, and packaging to produce various seasoning powders. The production line is available in configurations with hourly outputs of 0.5 tons, 1 ton, 1.5 tons, and 2 tons. Different configurations utilize different machine models. The entire set of equipment can crush seasonings to fineness levels ranging from 10 mesh to 120 mesh, adjustable by changing different screens. The required space for the production line is approximately 15 meters in length, 3 meters in width, and 3 meters in height. The seasoning crushing production line can also be customized according to the available space.

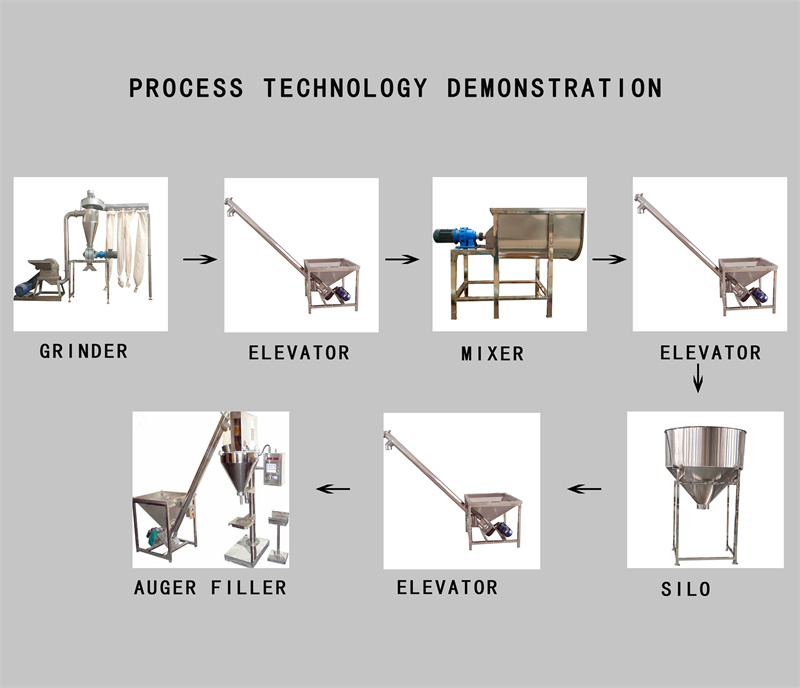

Process Flow of the Seasoning Crushing Production Line1. Seasonings are elevated via a belt conveyor or manually to a stainless steel disc crusher for crushing.

- The crushed seasonings are then elevated by a stainless steel screw conveyor to a stainless steel mixer for blending, ensuring the seasoning powder is mixed more uniformly.

- The mixed powder is then elevated by a stainless steel screw conveyor to a finished product bin, awaiting packaging.

- The finished powder from the bin is conveyed to the packaging machine for packaging. Packaging options include bag filling or bottle filling, with adjustable filling ranges.

Structural Composition of the Seasoning Crushing Production Line - Elevator (Belt Conveyor / Stainless Steel Screw Elevator): Uses an electric motor as the power source to convey powdered or irregular granular raw materials to specified locations, ensuring convenient and efficient feeding.

- Stainless Steel Seasoning Crusher (Single Dust Removal Crusher / Pulse Dust Removal Crusher)**: Utilizes the powerful shear, impact, and friction generated between two relatively high-speed rotating disc plates (one moving disc and one fixed disc) to crush materials into fine particles. It can crush seasonings into powder or granules. The crushing fineness is adjustable.

- Stainless Steel Mixer (U-type Ribbon Mixer / Drum Mixer): Uses the shear action of mixing blades to uniformly blend various powdered raw materials.

- Finished Product Bin: A bin for storing the finished powder.

- Powder Packaging Machine**: Suitable for packaging powdered materials, fine powders, and small granules. Features a Chinese/English touch screen display for intuitive and simple operation. A PLC computer control system ensures more stable operation and allows parameter adjustments without stopping the machine. It can store ten sets of parameters, enabling more accurate product changeovers.

The entire set of equipment in the seasoning crushing production line is made of 304 stainless steel. The surface is smooth without dead angles, making it easy to clean and disinfect thoroughly, fully complying with the standard requirements of the food and pharmaceutical industries. It offers strong corrosion resistance: capable of handling materials containing water, acid, salt, or other somewhat corrosive substances, ensuring a long equipment lifespan.

Industries for the Seasoning Crushing Production Line

- Food Industry: Crushing of sugar, grains, cereals, spices, seasonings, chili, Sichuan pepper, black pepper, cumin, cinnamon, nutmeg, bay leaves, star anise, cardamom, dehydrated onions, beans, starch, food additives, etc.

- Pharmaceutical Industry: Fine crushing of Chinese herbal medicines, plant extracts, active pharmaceutical ingredients (APIs), excipients, etc.

- Chemical Industry: Crushing of pigments, dyes, resins, alumina, bentonite, cat litter, fertilizers, sea salt, chemical raw materials, etc.

- Other Industries: Feed, tobacco, non-metallic minerals, etc.

Operation and Maintenance of the Seasoning Crushing Production Line

Before Operation: Check that all parts of the equipment are tight and ensure there are no foreign objects in the crushing chamber. Start the machine under no load and begin feeding only after it runs normally.

During Operation: Feed materials evenly to avoid blockages or motor burnout caused by excessive speed or overload. Pay attention to the operating sound and current of the equipment; immediately stop and inspect if any abnormalities are found.

After Operation: Clean the equipment to prevent cross-contamination and bacterial growth.

Regular Maintenance: Regularly check the wear of the disc plates; replace them promptly if severely worn to ensure crushing efficiency. Regularly apply lubricating grease to transmission parts such as bearings.