Stainless Steel Spice Grinder

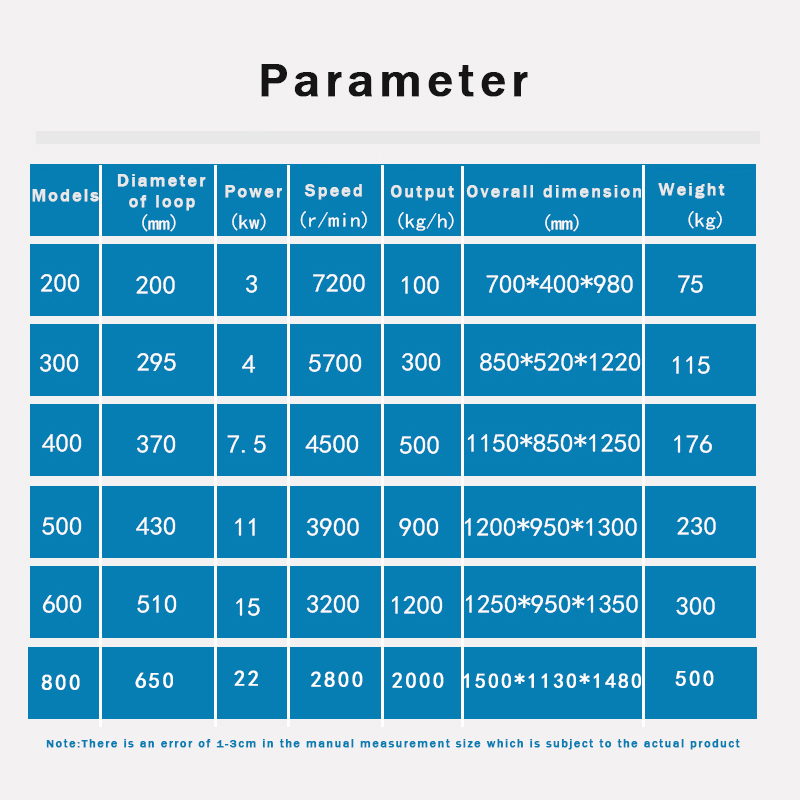

The Stainless Steel Spice Grinder is a claw-type grinder made entirely of 304 stainless steel. It is commonly used for grinding spices, with an hourly output ranging from tens of kilograms to several tons. It can serve as a spice processing equipment. The Stainless Steel Spice Grinder can be categorized into the following types: basic grinder unit, single cyclone dust collector grinder, pulse dust collector grinder, water-cooled grinder, and self-priming grinder. The choice of model depends on the raw materials being processed. The fineness of the grinding can be adjusted from 10 mesh to 120 mesh.

Basic Spice Grinder Unit: Refers to just the grinder without any dust collection system. The ground material is directly collected into a bag. The working process involves pouring the raw material directly into the grinder, and the product is discharged instantly. This unit is suitable for small output grinding or for processing high-density raw materials.

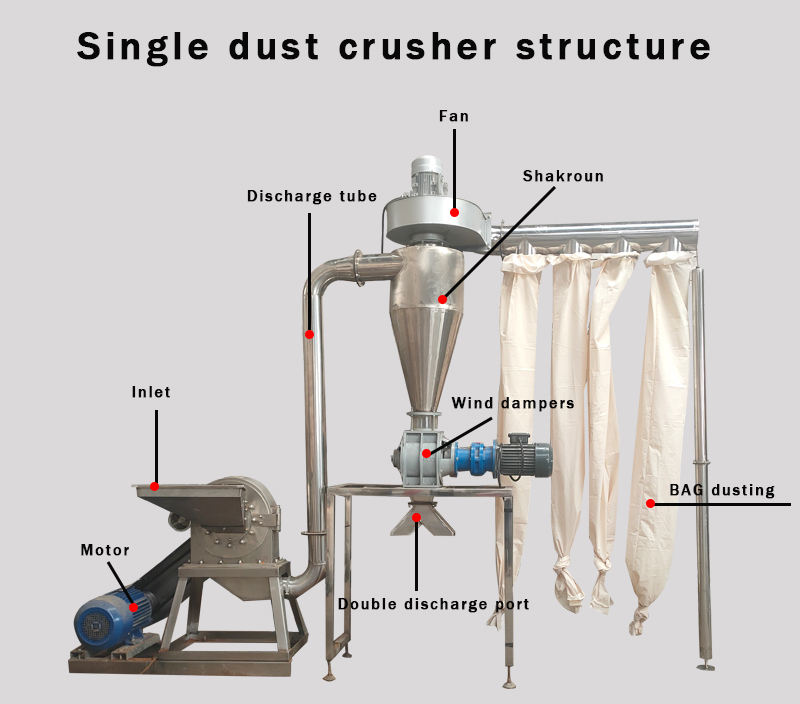

Single Cyclone Dust Collector Spice Grinder: Refers to a stainless steel disc grinder whose discharge outlet is connected to a single cyclone dust collector. This system mainly consists of the grinder host, cyclone dust collector, airlock discharger, and fan. The working process involves the grinder crushing the material, which is then blown by the fan into the cyclone dust collector, and finally discharged through the airlock discharger. The benefits are windless and dust-free discharge via gravity fall. The discharge outlet is about 80 cm from the ground for easy collection.

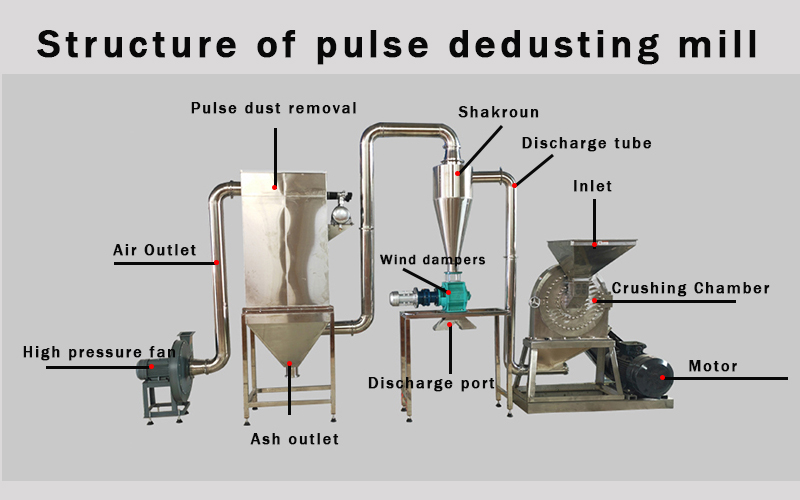

Pulse Dust Collector Spice Grinder: This is a stainless steel grinder connected to both a single cyclone and a pulse dust collector, internally equipped with a 12-bag dust removal system, and made of 304 stainless steel. This grinder can be used for grinding chili peppers or chemical raw materials. It primarily reduces workshop dust and odor. The discharge height is also 80 cm for convenient collection.

Self-Priming Spice Grinder: The feed inlet is directly replaced with a self-priming pipe and suction plate. The rear end can be connected to a cyclone dust collector or a pulse dust collector. It is generally used for grinding small particle raw materials, grain materials, or powdered materials. Self-priming feeding facilitates easy loading, saves labor, and improves grinding efficiency.

Water-Cooled Grinder: Both the rotating disc and the fixed disc are equipped with internal hollow water-cooling jackets. Circulating cooling water continuously flows through these jackets, acting like an “air conditioner” for the machine’s “heart,” efficiently and continuously carrying away the heat generated during the grinding process, ensuring the material temperature remains low. It is used for grinding heat-sensitive materials or materials susceptible to heat, such as sugar and chicken bouillon.

Processable Materials

The Stainless Steel Spice Grinder can grind:

Barbecue seasonings, chili peppers, pepper, Sichuan pepper, cardamom, white cardamom, Chinese prickly ash, cinnamon, bay leaves, cumin, fennel, curry leaf, white pepper, black pepper, star anise, galangal, dried ginger slices, dried garlic slices, various compound seasonings, salt, sugar, monosodium glutamate (MSG), chicken bouillon, dry and hard brittle raw materials. It can also grind rice, corn, mung beans, soybeans, black beans, black rice, purple rice, glutinous rice, puffed foods, chemical pellets, chemical raw materials, industrial salt, and sea salt.

Usage and Maintenance

No-load Startup: It is strictly forbidden to start the machine with material inside. Material should be fed evenly only after the equipment is fully started and operating normally.

No Metal Foreign Objects: Strictly check before feeding to prevent metal or other hard foreign objects from entering the chamber, which could damage the claw disc and screen.

Regular Inspection: Regularly check the wear of the claw disc, any damage to the screen, and whether fasteners are loose.

Timely Cleaning: The equipment must be thoroughly cleaned after each use to prevent cross-contamination from residual material or corrosion. Protect the motor and bearings from water during cleaning.

Cooling Water Maintenance: Ensure the cooling water circuit is clear and the water quality is clean to prevent scale blockage. In areas with low environmental temperatures, drain the cooling water after prolonged shutdowns to prevent the jackets from freezing and cracking.